Fleet Online

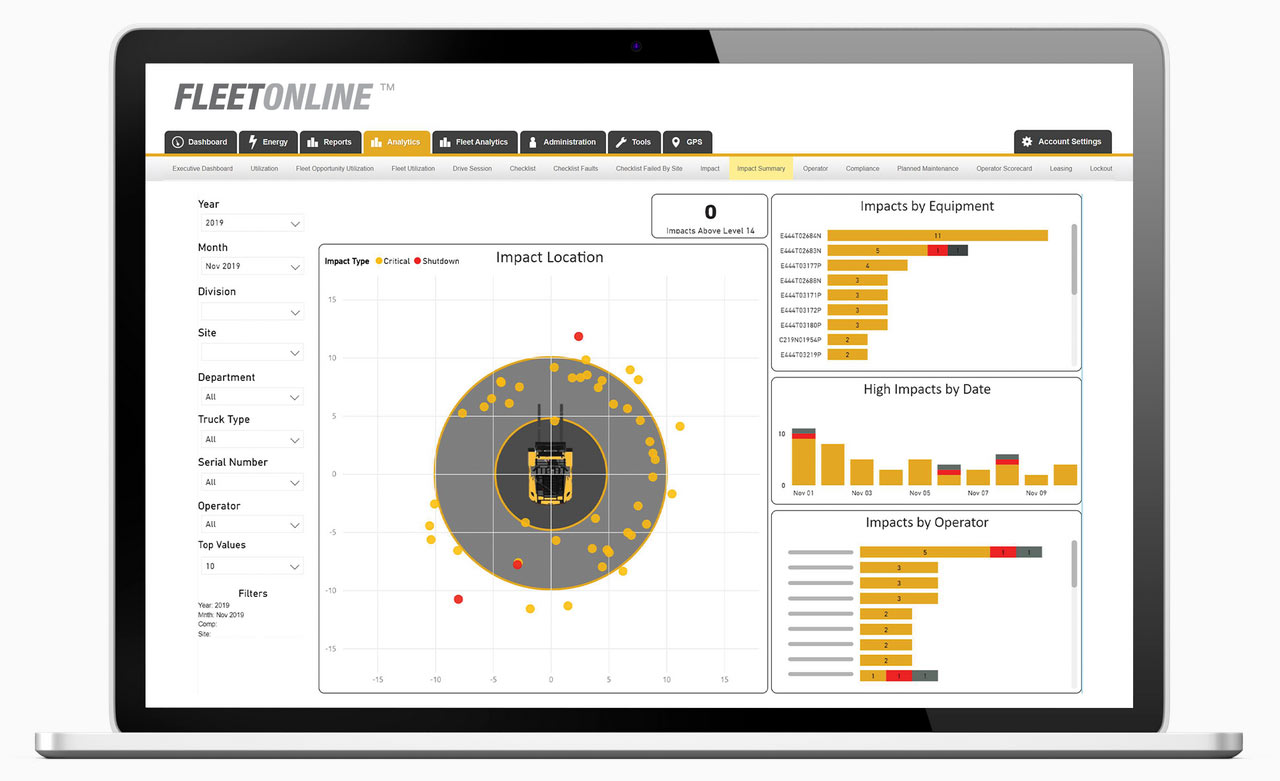

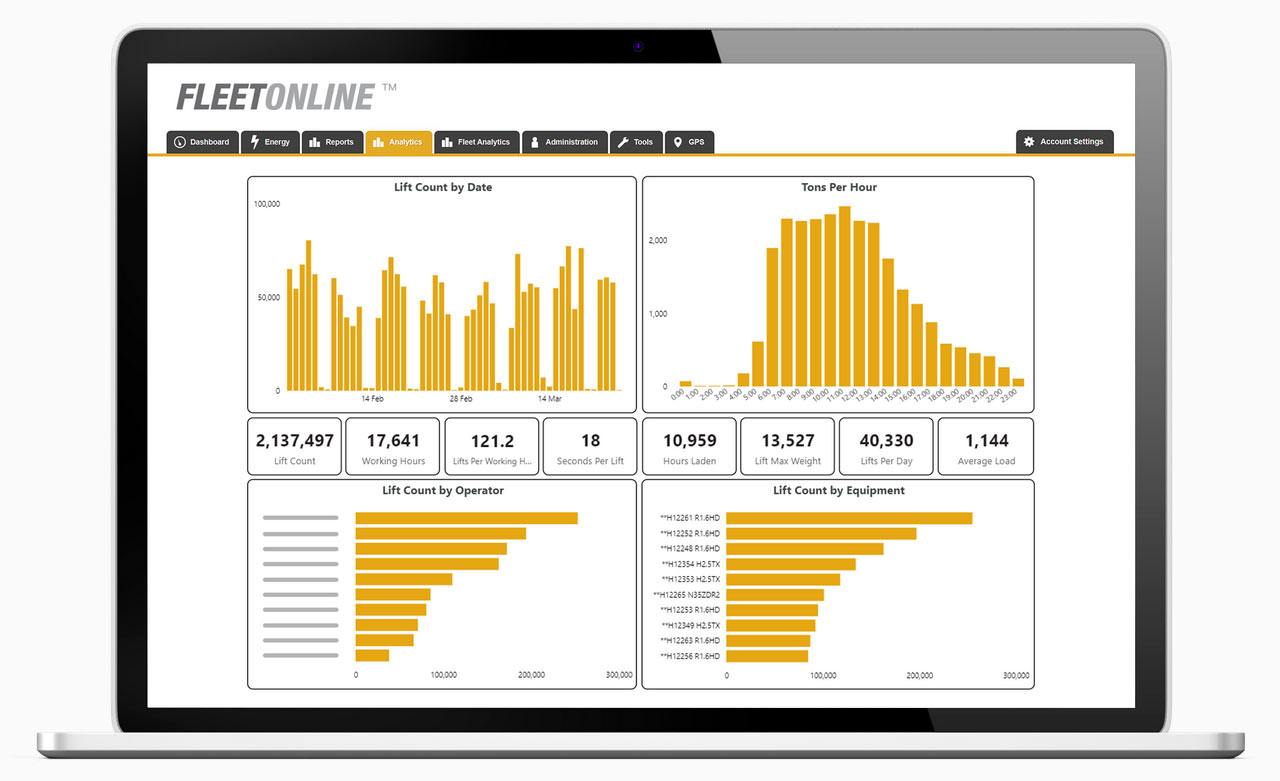

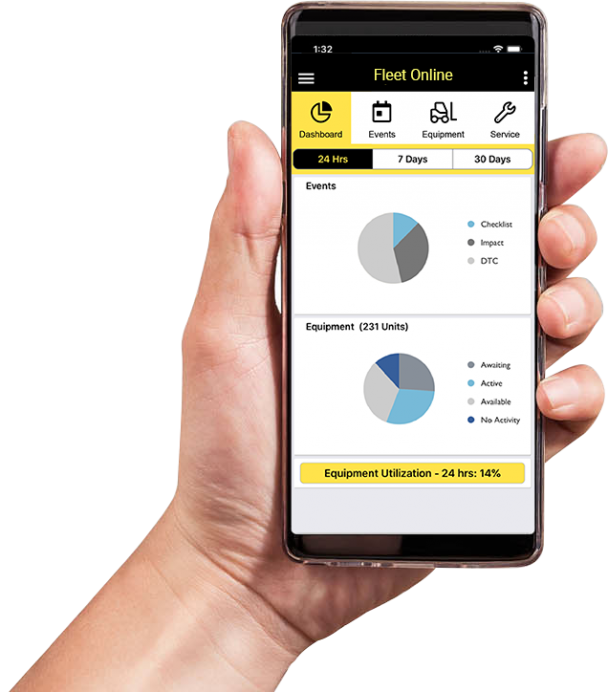

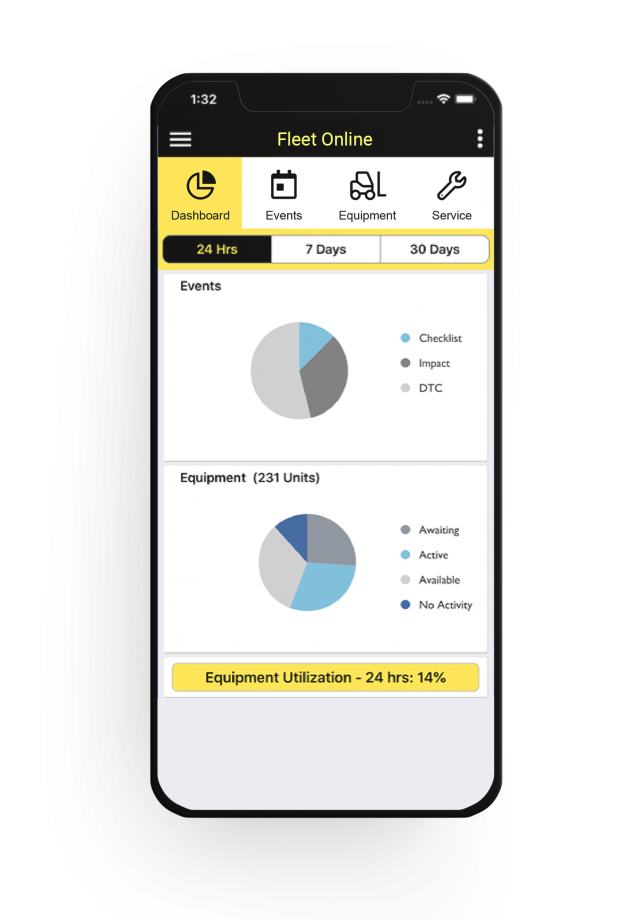

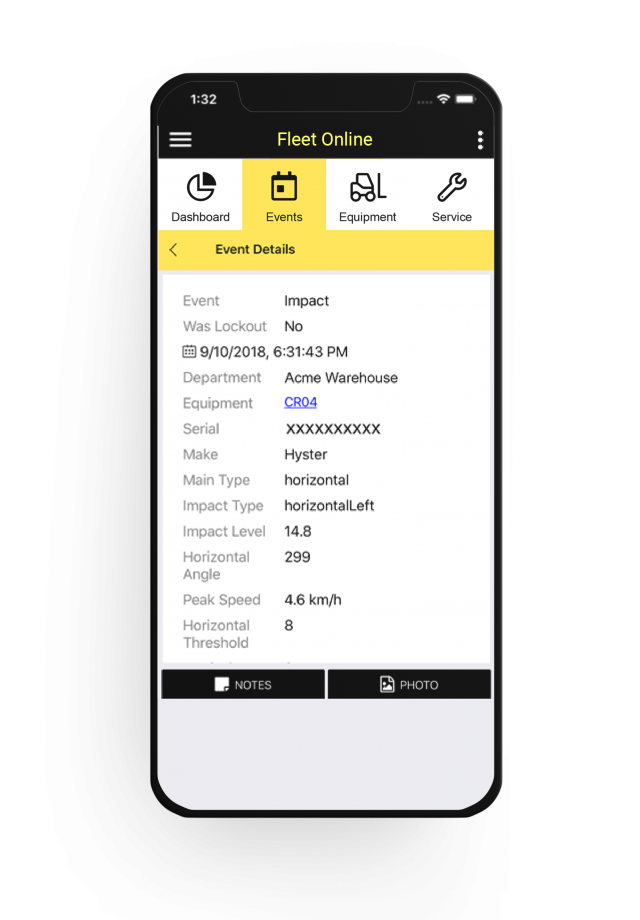

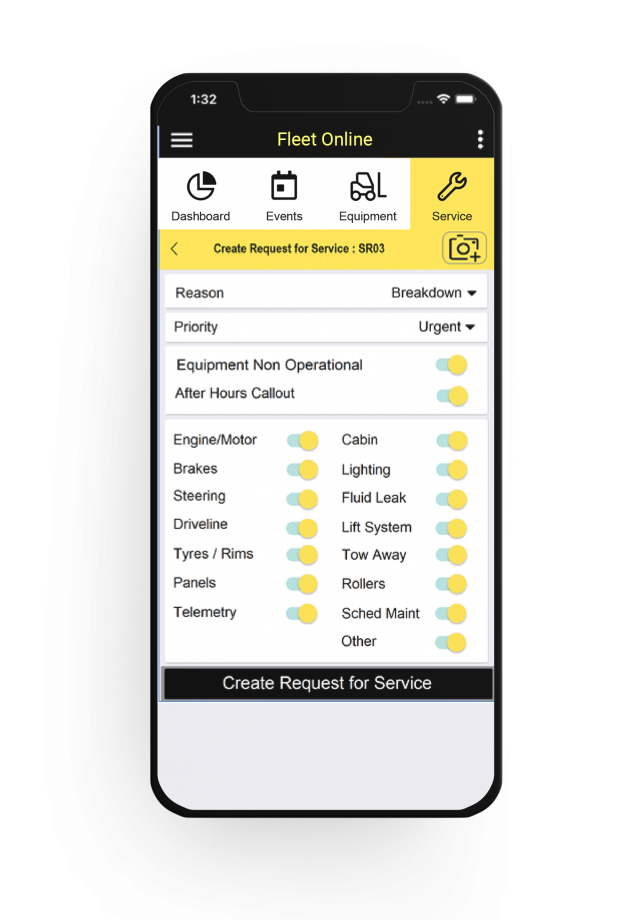

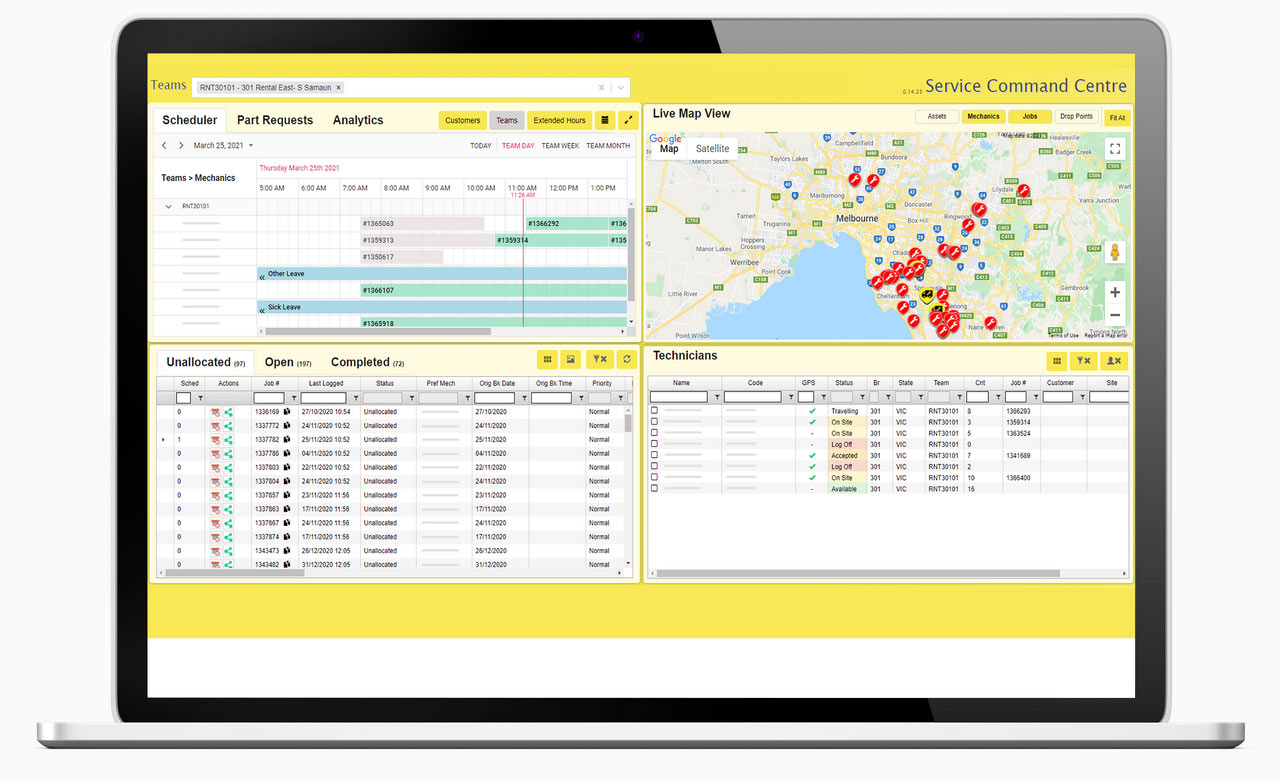

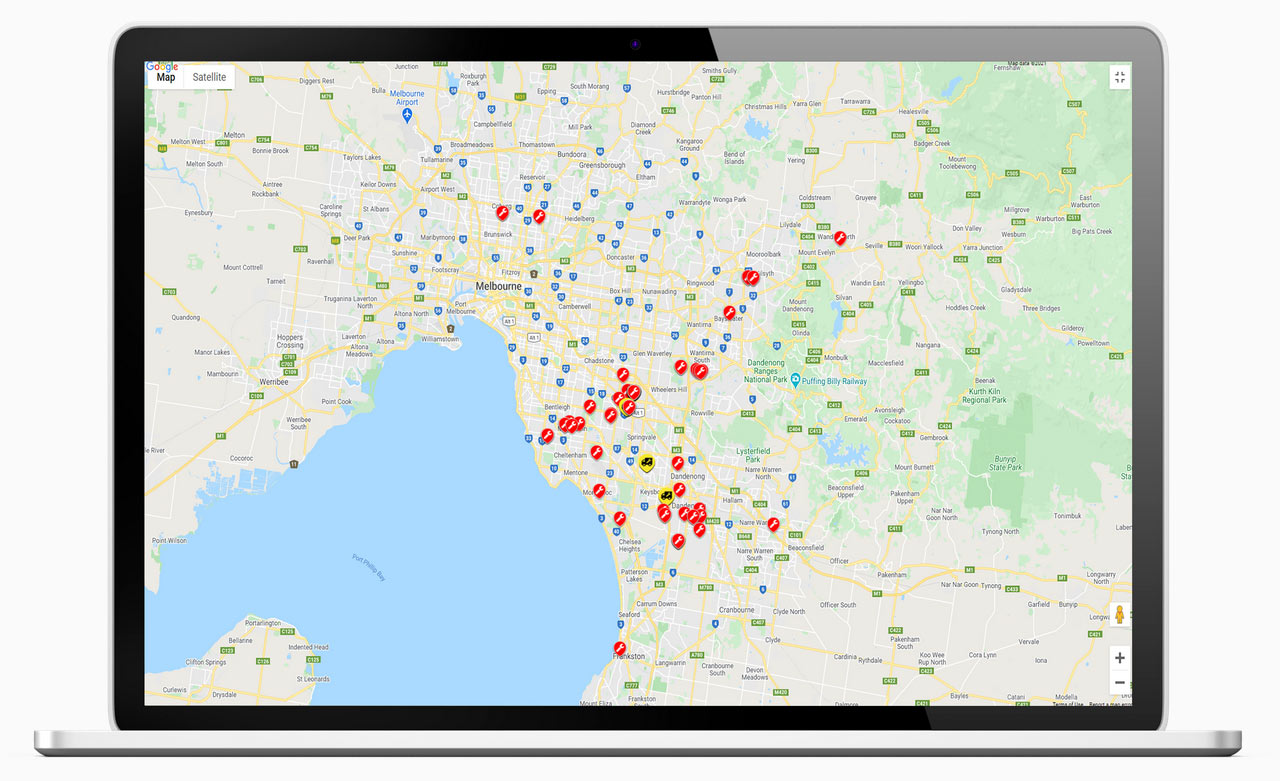

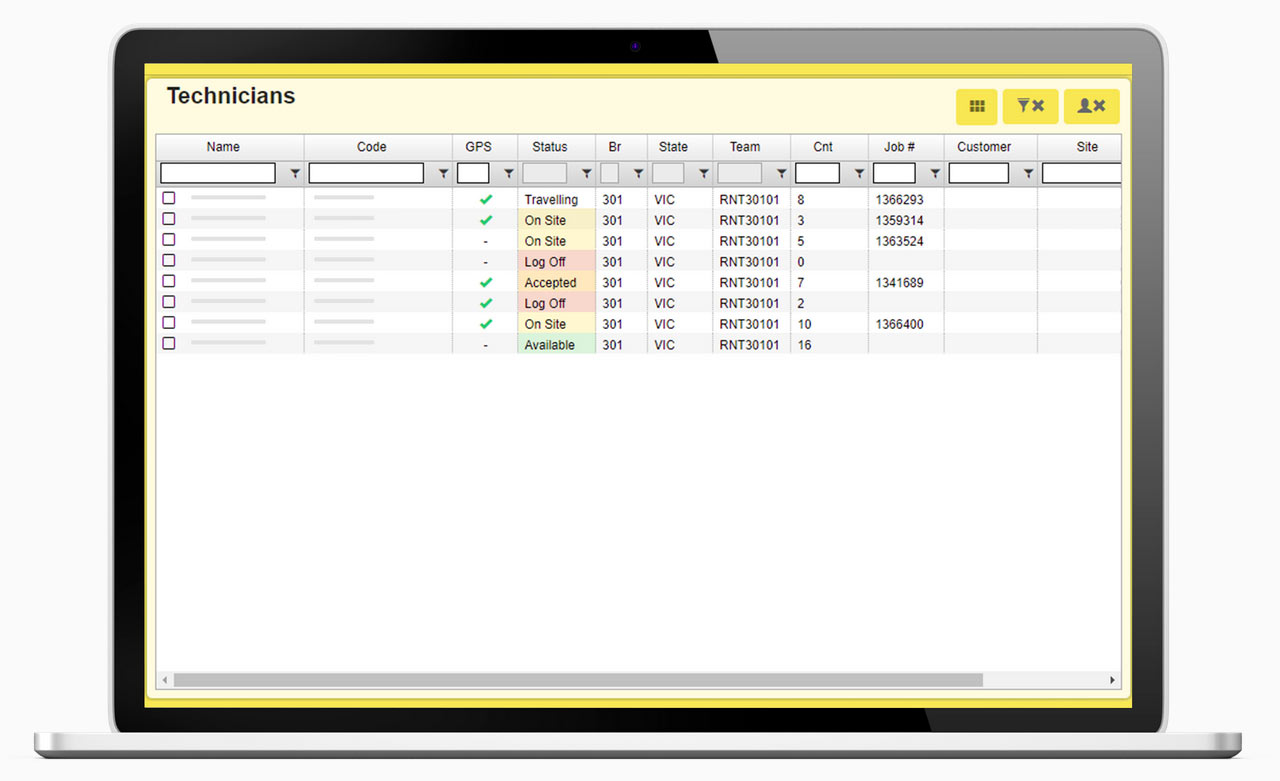

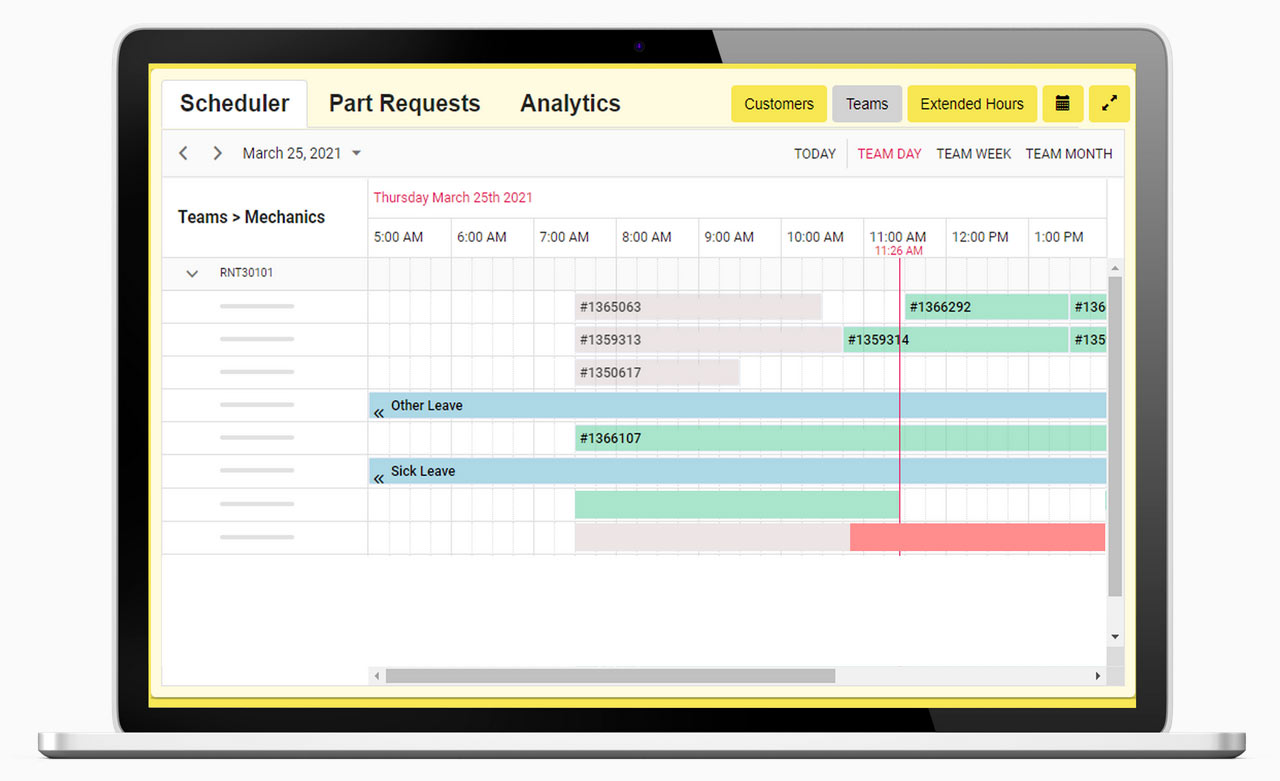

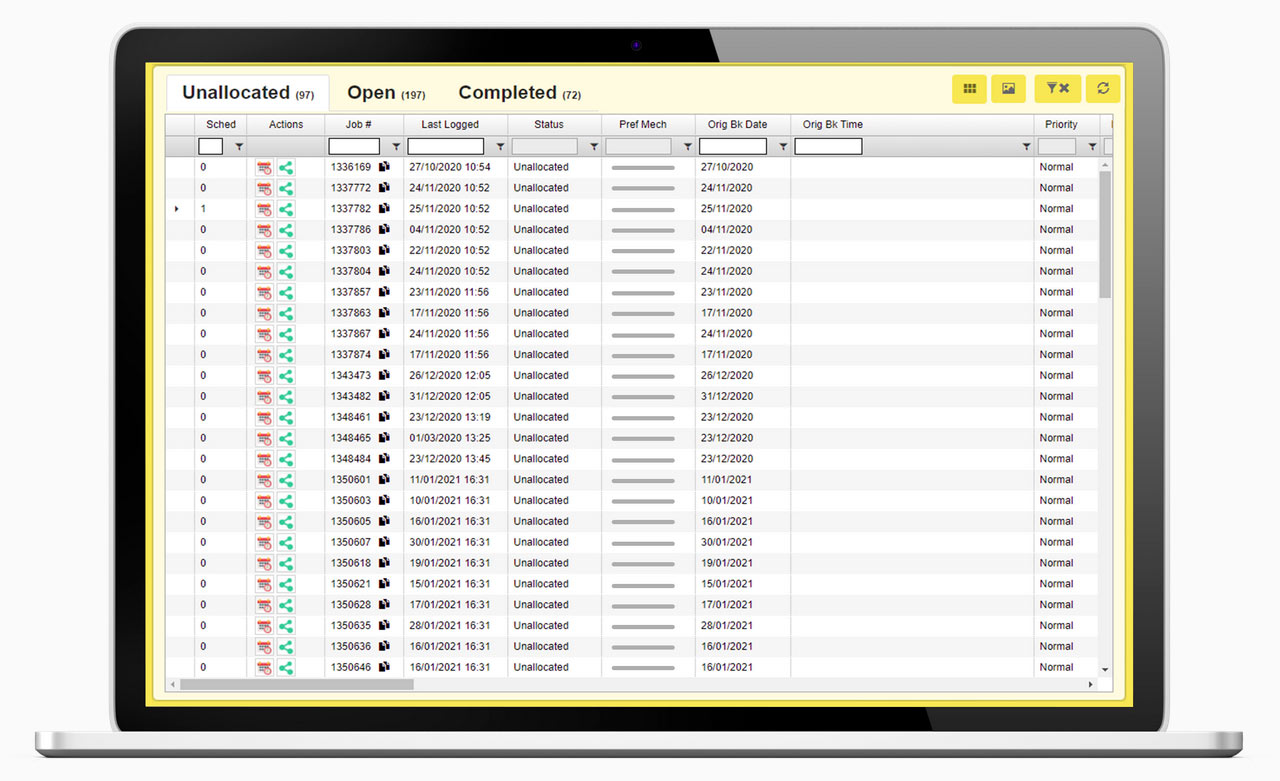

Fleet Online combines advanced safety features with an unprecedented level of analytical insight and fleet efficiency.

- The platform reduces fleet running costs via instant monitoring and control, fleet analytics dashboards, real-time web-based reporting and operator accountability & performance.

- Fleet Online integrates seamlessly with the award winning Speedshield product range including: VAM, FM2, Zoned Speed Control, Variable Speed Limiting, Lift Height Monitoring and all our Energy Management hardware. view our devices here.

Speedshield are able to white label and customise the Fleet Online platform to suit your brand.